Concept

Description and procedure

Standard Penetration Test, SPT, involves driving a standard thick-walled sample tube into the ground at the bottom of a borehole by blows from a slide hammer with standard weight and falling distance. The sample tube is driven 150 mm into the ground and then the number of blows needed for the tube to penetrate each 150 mm (6 in) up to a depth of 450 mm (18 in) is recorded. The sum of the number of blows required for the second and third 6 in. of penetration is reported as SPT blowcount value, commonly termed "standard penetration resistance" or the "N-value".

The N-value provides an indication of the relative density of the subsurface soil, and it is used in empirical geotechnical correlation to estimate the approximate shear strength properties of the soils.

Correlation between SPT-N value, friction angle, and relative density

|

SPT N3 |

Soi packing

|

Relative Density [%]

|

Friction angle

[°] |

|

< 4

|

Very loose

|

< 20

|

< 30

|

|

4 -10

|

Loose

|

20 - 40

|

30 - 35

|

|

10 - 30

|

Compact

|

40 - 60

|

35 - 40

|

|

30 - 50

|

Dense

|

60 - 80

|

40 - 45

|

|

> 50

|

Very Dense

|

> 80

|

> 45

|

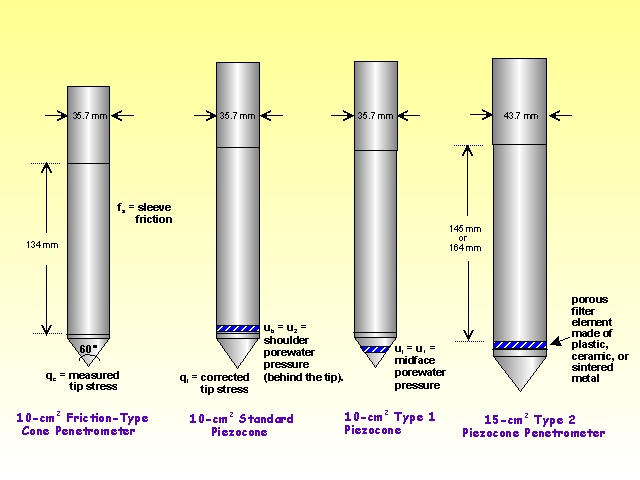

The Cone penetration test can be carried out from the ground surface with a need for a borehole. The test is carried out by first pushing the cone into the ground at a standard velocity of 1 to 2 cm/s while keeping the sleeve stationary.

For any depth, the resistance of the cone, called cone penetration resistance q_c , is recorded using the force probes provided for this purpose in the cone. Then the cone and the sleeve and moved and penetrated together into the soil and the combined cone and sleeve resistance, indicated by q_t , is recorded at any depth using tension load cells embedded in the sleeve.

This procedure is repeated and the measurements are made at regular depth intervals during penetration. In addition to the stress on the tip and the sleeve friction, the typical CPT probe measures as well the porewater pressure. Some equiped CPT probles are also able to measures shear wave velocity and temperature.

The cone penetration resistance values can be then correlated to shear strength parameters using proposed empirical curves. There are also some design methods associated with CPT results which directly use the CPT results to estimate the settlement is soils under a given pressure.

Standards

- BS 1377-7:1990

- ASTM D3441 - 05 Standard Test Method for Mechanical Cone Penetration Tests of Soil Link

- ASTM D5778 - 07 Standard Test Method for Electronic Friction Cone and Piezocone Penetration Testing of Soils Link

References - External Links

- General description of Cone Penetration Test,The Center for Public Environmental Oversight (CPEO)

- Detailed description of Cone Penetration Test, parameters and sample Logs,J David Rogers, Lecture notes, Advanced Engineering Geology & Geotechnics, Missouri University of Science and Technology

- Cone Penetration Test on Wikipedia

- Simple illustration of description of CPT procedure with photos,R. W. Boulanger, University of California at Davis

- Soil Classification Using the Cone Penetration Test,P. K. Robertson, Canadian Geotechnical Journal, Vol, 27, pp. 152-158, 1990Link